|

|

Build Your Online Product Catalogs?

| Product Name: |

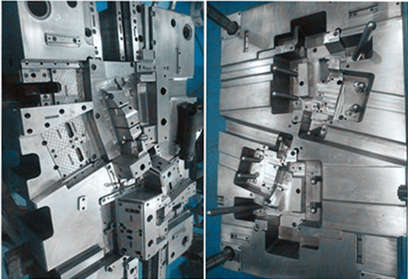

Plastic Injection Mold

|

| Supply Ability: |

|

| Related proudcts |

mould, injection mold, plastic mold, |

| Specifications |

Aco Mold China |

| Price Term: |

FOB |

| Port of loading: |

China Mold |

| Minimum Order |

1set |

| Unit Price: |

1USD |

|

There is very little unemployment for anyone with technical skills (especially those where a 4 year degree is required). Plastic injection mold co***nies that make high quality products and treat their employees well attract candidates. Managers that are push their people too hard should keep in mind that employees have choices.

The buzz in the industry has been on aluminum production plastic injection molds as a way to get the heat out of a mold quickly and reduce cycle times. Using high-thermal conductivity metals, like beryllium copper and aluminum, achieve cycle reductions of 20% or more. With the industry looking for every penny, there is a paradigm shift on how aluminum is viewed as a production mold. Aluminum is less expensive than beryllium copper, and with a 20% reduction in cycle time and the potential to machine the mold 10% - 20% faster, what's not to like? However, aluminum is not for every application. It's softer than steel and the molding people need to be trained in the care and feeding of production aluminum molds. Coatings can provide a hard surface, but the substrate will still be soft. Hard coat anodizing the aluminum will increase the surface hardness to about 58 Rc. The growth thickness above the surface will equal the substrate penetration. Some plastic mold coatings can reduce the coefficient of friction, between the resin melt and the mold, which produces longer flow lengths in the plastic injection mold.

I know of facilities that have done this in rural MN, IA, and WI. There are some wonderful plastic injection mold co***nies and people in the industry that have great training courses. I am not sure if provides this as a service as well, but if you would like some referrals let me know, and I will start connecting you with the right people. |

| Company: |

Aco Injection Mold Manufacturing

|

| Contact: |

Mr. Mike Huang |

| Address: |

No.7 fuhai fuyong |

| Postcode: |

518000 |

| Tel: |

8675599153265 |

| Fax: |

8675599153264 |

| E-mail: |

|

|

|

|